Extend Equipment Life Up to 30x with Thermal Spray: HVOF, Tungsten Carbide & HFW 512

HFW Industries is a pioneer in thermal spray services, specializing in high-performance coatings like tungsten carbide and HVOF coatings to combat wear, corrosion, and replace hard chrome. With over 70 years of experience and as the first commercial licensee of the Norton Rokide® process in 1957, HFW has helped customers save millions by extending equipment life, reducing downtime, and restoring critical components to OEM dimensions.

From industrial rolls to turbine shafts, pump sleeves, and bearing surfaces, our thermal spray services deliver engineered surfaces that meet extreme operating demands. Read further down the page for an overview of our capabilities (including HVOF), our thermal spray gallery, and the industries we serve.

Request a Quote

📧 Request a Quote: RFQ@hfwindustries.com or 📞 Call us at (716) 875-3380

Contact Us to Discuss a Personalized Solution: Contact Form

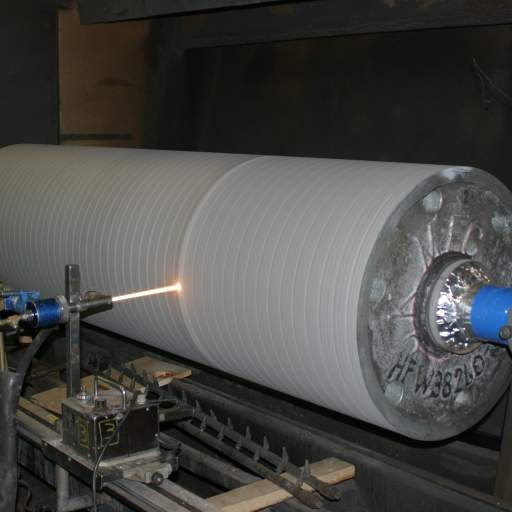

Take a Look Inside Our Plant: Thermal Spray Gallery

At HFW Industries, precision and performance drive everything we do. Our thermal spray technologies—including plasma spray, high velocity oxy-fuel (HVOF), and electric arc metallizing—enhance component durability, reduce downtime, and extend equipment life across a wide range of industries.

What Is Thermal Spraying and How Does It Protect Industrial Equipment?

Thermal spraying is when a coating material (in powder, rod or wire form) is heated to a designated temperature and then propelled in a molten state onto a substrate. The result is a mechanically bonded coating that will restore size or protect the substrate in the application.

Technical advantages of thermal spray coatings:

- Minimal part distortion (<300°F application)

- Customizable coatings with precise surface properties

- Versatility in materials and substrate types

Operational benefits of thermal spray coatings:

- Components can be re-engineered using higher-performance materials

- Reduces or slows wear

- Improved functionality and life of process-related or OEM equipment

- Improved lead time—repairing components vs. manufacturing

- Obsolete parts no longer available from the OEM are able to be repaired/salvaged

- Enhance the lifespan of new equipment—HFW has achieved 30x improvement in service life

HFW's engineering team carefully considers your job to select an appropriate coating—such as HVOF coatings, tungsten carbide coatings, or proprietary alloys—to ensure each component is optimized for performance, durability, and precision.

Comprehensive Thermal Spraying Capabilities at HFW

HFW integrates thermal spray services with our full manufacturing capabilities, including welding, machining, precision finishing, and assembly. We offer a wide range of processes to meet any application:

Flame Spray (Wire & Powder Metallizing)

- Wire or powder feedstock melted by oxygen-fuel gas flame

- Compressed air propels the molten particles

- Ideal for restoration, dimensional build-up, and general wear resistance

Electric Arc Wire Spray

- Two wires arc electrically at the gun’s tip

- Molten droplets atomized and sprayed with air

- Economical and fast, often used on large surfaces

Plasma Spray

- Ionized gas (plasma) melts the coating powder

- Powder propelled by kinetic energy to the substrate

- Excellent for ceramics, cermets, and high-melting-point metals

High Velocity Oxy-Fuel (HVOF)

- Extremely dense, high-velocity coatings

- Best for wear-critical and corrosion-resistant coatings

- Frequently uses tungsten carbide coatings, Stellite® alloys, chromium carbide, and more

Rokide Flame Spray (Ceramic Rod)

- Ceramic rods melted with oxy-fuel flame and sprayed with air

- Provides thermal insulation, electrical resistance, and corrosion protection

- HFW was the first commercial licensee of the Norton Rokide process in 1957

Spray Welding (Thermal Spray + Fusing)

- Self-fluxing alloy powder sprayed onto surface

- Then fused to base metal via torch

- Results in metallurgically bonded, hard, and uniform overlay

Materials we apply include:

- Metals & Metal Alloys: Nickel/Chrome, Hastelloy® C, Inconel® 625/718, Stainless Steel, Monel, Copper, Molybdenum

- Carbides: Tungsten carbide/cobalt (WC/Co), tungsten carbide/nickel, chromium carbide/nichrome

- Cobalt-based Alloys: Stellite #6 alloys, Tribaloy®

- Ceramics & Cermets: Alumina, Zirconia, Chrome Oxide, and more

We tailor thermal spraying materials and processes for your part geometry, operating environment, and performance requirements.

Specialty Solution: HFW’s Proprietary Alloys

HFW has developed proprietary thermal spray alloys like HFW 512, which has delivered a 30x improvement in service life in chemical processing rolls. These alloys, combined with our HVOF thermal spray process, offer:

- Exceptional wear and corrosion resistance

- Long-term cost savings and reduced downtime

- Proven results backed by decades of field data

In addition to HFW 512, we maintain a suite of other HFW alloys, enabling customized coatings for challenging applications. For specific technical information on HFW alloys, please connect with our team to receive our material data sheets.

Industries and Applications We Serve

HFW’s thermal spraying services can be used across a wide range of industries:

- Chemical Processing

- Power Generation and Turbomachinery

- Oil & Gas

- Mining

- High Tech

- Paper & Pulp

- Advanced Manufacturing and Heavy Industry

Common applications include:

- Abrasion and erosion protection

- Corrosion protection in chemical or marine environments

- Heat shielding and electrical insulation

- Anti-slip or anti-stick surfaces

- Radio frequency (RF) shielding for sensitive components

- Size restoration of worn or mis-machined parts

Why Choose HFW? Quality, Reliability, and No Excuses

HFW is your one-source thermal spray services provider, integrating coatings with machining, finishing, and assembly. Our approach ensures:

- Reduced lead times and downtime

- Elimination of multi-vendor coordination

- Consistent quality from start to finish

- Expert guidance in material and process selection

We combine decades of thermal spray expertise with precise process control to deliver coatings that perform under extreme conditions.

Ready to Discuss Your Project?

If you have a part that needs protection or repair, contact HFW today to discuss which HVOF thermal spray coating or thermal spraying service is right for your application. Below, explore our thermal spray photos and read an in-depth explanation of HVOF.

📞 Call us at (716) 875-3380 or use our Contact Form

📧 Email: RFQ@hfwindustries.com

Explore Our Thermal Spray Knowledge Base:

Dive deeper into the processes, materials, and real-world applications that make HFW a leader in surface restoration.

- Overview of Thermal Spray Coatings: HVOF & Tungsten Carbide — Why these materials are key to high-performance surface protection

- What are Key Thermal Spray Coating Characteristics? — Explore some of the key factors that determine thermal spray coating performance

- What is Thermal Spraying? — A beginner-friendly overview of the process and materials used

- HVOF -- A Superior Alternative to Chrome — Why HVOF coatings often outperform chrome in durability, cost, and turnaround time

- How HFW Extends Equipment Life — Real-world example of innovation in action

- Thermal Spray for Power Industry Applications — Combining thermal spray with in-house repair capabilities

- Thermal Spray in Chemical Processing — Coating solutions for corrosive and high-temp environments

- HVOF Thermal Spraying with Tungsten Carbide — An in-depth technical look at one of our specialties

HVOF Overview: High Velocity, High Performance

What is HVOF Thermal Spraying?

HVOF (High Velocity Oxy-Fuel) is one of the most advanced thermal spray techniques in use today. In this process, powdered material—such as tungsten carbide/cobalt or Stellite #6 alloys—is heated in a high-pressure flame and propelled at supersonic speeds onto the surface. The result is an extremely dense, hard, and low-porosity coating that provides exceptional resistance to wear, heat, and corrosion.

Why Choose HVOF?

- Very dense coatings with minimal porosity

- Chemical resistance: Especially important in corrosive environments

- Lower risk of hexavalent chromium exposure

- Precise control over material characteristics and thickness

- Ideal for finishing: HVOF coatings can be ground or polished to extremely fine surface finishes

Common Materials for HVOF:

- Tungsten Carbide/Cobalt – excellent for abrasion and erosion resistance

- Stellite #6 alloy – a cobalt-based alloy ideal for wear and corrosion

- Chromium Carbide – high-temperature oxidation resistance

- Nickel-Chrome-Boron alloy – great for hard, corrosion-resistant coatings

- Hastelloy C, Inconel 625/718 – exceptional in chemical and heat environments

HVOF vs. Hardfacing: What's the Difference?

Thermal spraying—particularly HVOF—and hardfacing are two widely used methods for protecting industrial components, but they differ significantly in process and application. HVOF thermal spray creates a mechanical bond between the coating and substrate, typically applied at low temperatures (usually under 300 °F). This process does not melt the base metal, resulting in no material dilution, and it allows for coating finished parts without distortion. HVOF coatings are generally layered and porous, depending on process parameters. Common materials used in HVOF include ceramics, carbides like tungsten carbide, and various metals, making it ideal for precise, low-heat applications where wear, corrosion, or thermal resistance is critical.

In contrast, hardfacing involves creating a metallurgical bond by welding or fusing material directly to the base surface, which typically occurs at high temperatures. This results in some dilution with the base metal, forming a homogenous alloy weld. Hardfacing is most commonly performed with nickel-, cobalt-, or iron-based alloys, and it is better suited for heavy-wear, high-heat, and structural applications where durability and impact resistance are essential.

So, when is HVOF preferred? When you need tight tolerances, fine finishes, and excellent surface performance without altering the part’s base structure. If you're restoring or enhancing rolls in galvanizing lines or high-speed rotating equipment, HVOF coatings with materials like tungsten carbide or Stellite alloys are ideal.

Attribution Statements

- Rokide® is a registered trademark of SAINT-GOBAIN CERAMICS & PLASTICS, INC.

- Stellite® is a registered trademark of KENNAMETAL INC.

- Hastelloy® is a registered trademark of HAYNES INTERNATIONAL, INC.

- Inconel® is a registered trademark of HUNTINGTON ALLOYS CORPORATION.

- Tribaloy ® is a registered trademark of KENNAMETAL INC.