Improve Service Life Up to 5 Years with Hardfacing: Power Generation, Oil & Gas, and Chemical Equipment

Industrial components exposed to abrasion, erosion, heat, and corrosion require more than standard repairs. They need engineered hardfacing and weld overlay services that prevent failure and extend service life. For over 75 years, HFW Industries has delivered proven hardfacing solutions for power generation, chemical processing & plastics, oil & gas, mining & extraction, high-tech, and OEM applications, backed by deep metallurgical knowledge and our comprehensive welding and machining facilities.

Founded in 1950 as Hard Face Welding & Machine Co., Inc., HFW offers decades of experience and expertise in Stellite® hardfacing, cobalt- and nickel-based overlays, PTA welding, and chromium-molybdenum steel restoration. We strive to be a trusted partner for reliability and maintenance teams seeking long-lasting protection against wear.

Request a Quote

📧 Request a Quote: RFQ@hfwindustries.com or 📞 Call us at (716) 875-3380

Contact Us to Discuss a Personalized Solution: Contact Form

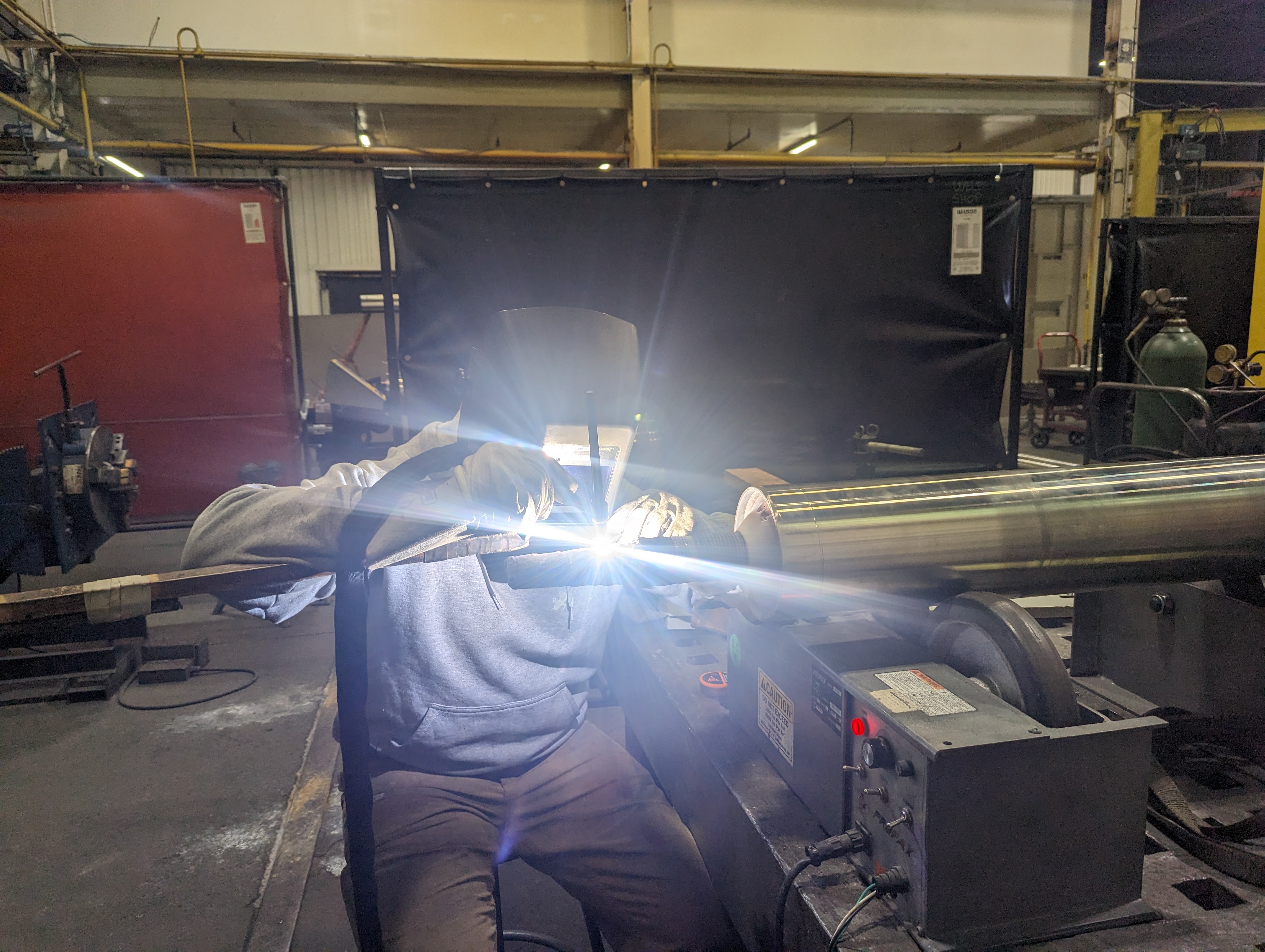

Take a Look Inside Our Plant: Hardfacing Gallery

At HFW Industries, precision and reliability are built into every weld. Our hardfacing capabilities—including TIG, MIG, and submerged arc welding—restore and protect critical components, reduce downtime, and extend service life in demanding industrial environments.

How Does Hardfacing Fit Into Our One-Source Model?

Hardfacing is most effective when supported by tightly controlled process steps before and after welding. HFW integrates surface preparation, weld overlay, machining, grinding, thermal spray, and inspection in one facility.

What the one-source difference looks like:

A valve seat arrives undersized and worn:

- Our machinists prepare the surface with proper geometry and depth

- Welders apply a metallurgically bonded overlay using PTA, TIG, MIG, or torch methods

- Preheat, interpass, and post-weld heat treatment follow strict, documented controls

- Precision machining and grinding restore OEM tolerances

- Final inspection includes visual, LP, and UT evaluation to ensure overlay integrity

This unified process reduces turnaround times, improves quality, and ensures repeatable weld overlay performance across all industrial applications.

Regardless of process, HFW weld procedures specify:

- Preheat temperatures

- Interpass temperature limits

- Post-weld cooling and heat treatments

- Weld pass sequencing and buttering techniques

- Filler metal size and feed rates

- Finishing methods and dimensional requirements

- Inspection methods, including visual, liquid penetrant, ultrasonic, and X-ray testing

Only with this level of discipline can hardfacing applications be repeatable, reliable, and resistant to delamination.

Customer Success Story: Five Years of Service With No Hardfacing Delamination

A large southeastern utility approached HFW after experiencing premature failure of their valve internals. Their existing components suffered from Stellite® #6 hardfacing delamination.

Component Details

- Valve Discs & Seats: 2.25% Cr–1.00% Mo steel (ASTM SA 387)

- Original Overlay: Stellite® #6

- Valve Stems: A286 iron-base superalloy (ASTM A638) — no overlay required

HFW’s Engineering-Driven Hardfacing Solution

HFW manufactured new discs, seats, and stems, and we then applied a controlled weld overlay procedure engineered specifically to prevent delamination. Key elements included:

- Proper preheat for SA 387 alloy

- Strict interpass temperature control

- Butter layers to control dilution and improve fusion

- Controlled post-weld cooling and thermal treatment

- CNC machining and precision grinding to final dimension

- Full inspection by an AWS Certified Welding Inspector using:

- Liquid Penetrant (LP)

- Ultrasonic Testing (UT)

The Result: Improved Service Life Up to 5 Years

The utility operated their valves in high-temperature service for five years with no signs of overlay failure, no cracking, and no delamination—a clear improvement over their previous supplier’s performance.

Why This Success Matters

This case highlights the importance of:

- Welding procedures informed by decades of experience

- Proper heat input management as well as post-weld cooling and treatments

- Correct alloy selection

- Integrated machining and finishing

It remains one of the strongest indicators of HFW’s reliability in power generation.

Comprehensive Hardfacing Capabilities at HFW

HFW’s weld overlay department combines decades of metallurgical expertise with modern equipment and ISO 9001:2015 quality controls. We provide complete hardfacing solutions for dimensional restoration, selective wear protection, and high-performance alloy buildup.

Hardfacing Processes

- TIG hardfacing

- MIG overlays

- Arc Welding

- PTA Welding (ideal for carbide and cobalt-based overlays)

- Oxy-Fuel Torch Welding

- Sprayweld (thermal spray + fuse)

Material Options

- Stellite® and cobalt-based alloys

- Nickel-based alloys

- Iron-based buildup alloys

- Specialty alloys for high heat, corrosion, impact, or chemical attack

- Alloys can be supplied in a rod, wire or powder form to suit the process being used

Capabilities Include:

- Selective hardfacing of new OEM components

- Complete restoration of worn parts

- Build-up prior to re-machining

- Extending service life in severe-duty applications

- Refurbishment of valve, pump, turbine, and process equipment components

Our extensive job record library allows us to repeat proven hardfacing applications, even years later.

Industries & Applications We Serve

HFW provides hardfacing for mission-critical components in:

Power Generation & Utilities

- Valve discs, seats, gates, stems

- Pump internals

- Turbine parts

- Sealing and wear surfaces

Oil & Gas

- Valve bodies and pump housings

- Rotors, shafts, and sleeves

- Corrosion- and sand-exposed components

Chemical Processing & Plastics

- Centrifuge bowls

- Agitator shafts

- Heated and coated rolls

- Chemical service wear components

Mining, Pulp & Paper, Heavy Industry

- Crusher rolls, scrapers, chutes

- Carbide overlays for severe abrasion

OEM Manufacturing

- Selective hardfacing on new components

- Repeatable overlays based on archived jobs

Why Choose HFW? Quality, Reliability, and No Excuses

- Seven decades of hardfacing expertise

- Industry-leading overlay reliability

- ISO 9001:2015 registered processes

- AWS-certified inspection

- Integrated machining, grinding, thermal spray & assembly

- Proven solutions for high-wear, high-heat environments

- Tight tolerances and consistent quality

- Documented procedures for repeatable success

Ready to Discuss Your Project?

Whether you’re combating wear, rebuilding critical industrial components, or replacing unreliable weld overlays, HFW delivers engineered hardfacing solutions built for long-term service.

📞 Call us at (716) 875-3380 or use our Contact Form

📧 Email: RFQ@hfwindustries.com

Our engineers can help you evaluate repair options, material choices, and overlay procedures tailored to your operating environment.

Explore Our Hardfacing Knowledge Base:

Dive deeper into the processes, materials, and real-world applications that make HFW a leader in hardfacing.

- Preventing Hardface Delamination — Explore practical lessons for improving the useful life of equipment derived from a case study on combatting Stellite® delamination for a utility

- Reducing Assembly Time by 75% at 1/3 the Cost — Learn how HFW's one-source strategy can streamline our customer's processes and rein in costs

- What are HFW's Hardfacing Capabilities? — Learn how HFW’s hardfacing expertise restores industrial equipment with proven weld procedures and precision inspection

- How Does HFW Serve the Turbomachinery Industry? — Learn about HFW's one-source repair and manufacturing strategy for turbines, rotors, and other turbomachinery equipment

What is hardfacing and how does it extend equipment life?

Hardfacing (also referred to as weld overlay) is a high-temperature welding process used to apply a wear-resistant alloy directly onto a base material. Unlike thermal spraying, hardfacing creates a metallurgical bond between the overlay and the substrate, resulting in a homogenous, fused layer that becomes part of the component itself.

Hardfacing is commonly used to restore worn components to OEM dimensions or to selectively protect new equipment from abrasion, erosion, corrosion, heat, and impact in severe-duty industrial environments. Hardfacing can be used for applications in the power generation, oil & gas, chemical processing & plastics, high-tech, mining, and other heavy industries.

Because the overlay is welded into the base material, hardfacing involves controlled dilution and requires precise management of heat input, metallurgy, and weld procedure to ensure long-term reliability.

What are the technical characteristics of hardfacing?

- High-temperature application process

- Metallurgically bonded overlay (not mechanical adhesion)

- Controlled dilution into the base material

- Homogenous, fused coating structure

- Excellent resistance to abrasion, erosion, corrosion, heat, and impact

- Suitable for rebuilding components or selectively protecting wear zones

- Hardfacing materials are most commonly nickel-, cobalt-, or iron-based alloys, including carbide-reinforced systems, supplied in wire, rod, or powder form depending on the welding process.

What causes hardfacing delamination?

Hardfacing delamination can be caused by process control issues such as improper preheat and interpass temperatures, unmanaged dilution, missing transition layers, or inconsistent post-weld cooling and heat treatment.

How long can hardfacing last in service?

When engineered and applied correctly, hardfacing can deliver multi-year service life. HFW's hardfacing solutions can remain in service for years under demanding operating conditions without delamination.

What is the difference between hardfacing and thermal spray?

Hardfacing creates a metallurgical bond by welding the overlay into the base material at high temperature. Thermal spray creates a mechanical bond at lower temperatures. Hardfacing is typically preferred for high-heat, high-load, or structural applications.

Why does one-source hardfacing matter?

A one-source approach keeps welding, machining, grinding, thermal spraying, and inspection coordinated within one facility. This reduces handoffs, improves process control, and ensures accountability for long-term performance.

Attribution Statements

- Stellite® is a registered trademark of KENNAMETAL INC.