May 10, 2021What is hardfacing? And can it reduce costs due to corrosion, wear and downtime?

The total cost of wear and corrosion on industrial equipment each year is so high it’s incalculable. There’s a lot of opportunity to increase your process up-time by improving your wear and corrosion resistance by using hardfacing!

Mechanical properties of many substrates don’t include inherent corrosion resistance and thus require hardfacing to enhance their performance.

Ask us how we help our customers with hardfacing technology when we combine it with our machining, finishing and assembly capabilities!

So What Is Hardfacing?

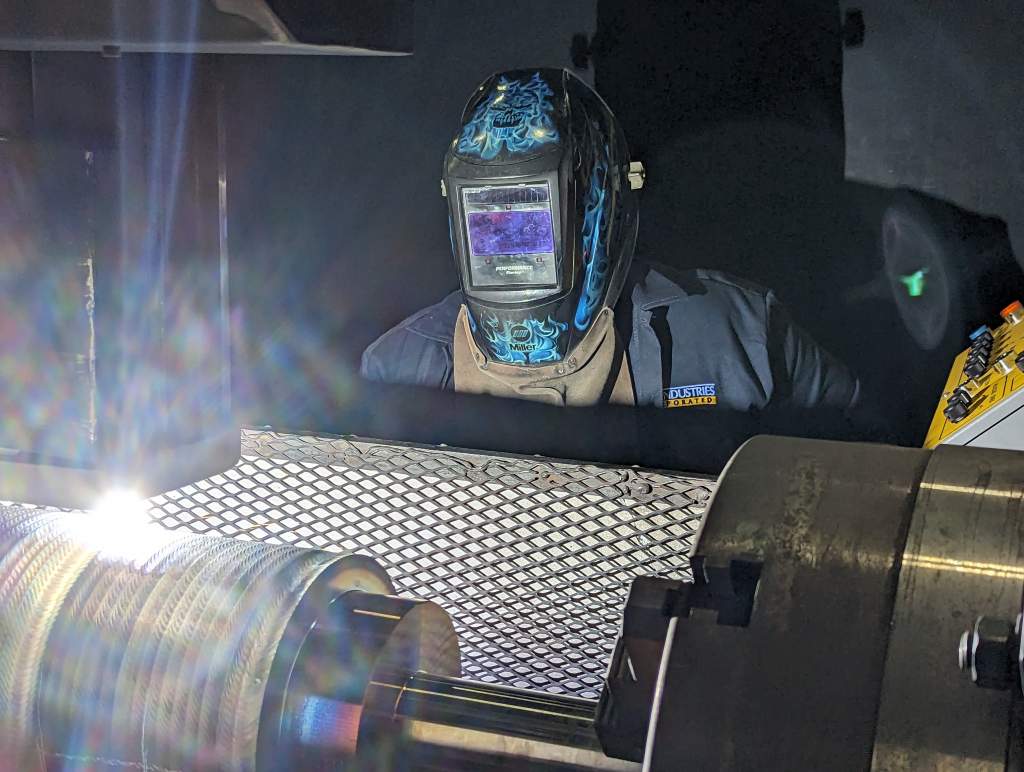

Hardfacing, or hardsurfacing, is a term used when a layer of weld overlay is applied over a base material in order to prolong the life or restore dimensions of the component. The bond formed between the overlay and base metal is metallurgical.

Methods for applying hardfacing include (but are not limited to):

- Plasma Transferred Arc

- Oxy-Acetylene Torch

- TIG/ MIG/ Sub Arc

Typical base materials that are hardfaced include:

- Low & Medium Carbon Steels (ex: 1020/ 1030)

- Alloy Steels (ex: 4140, 8620)

- Stainless Steels (ex: 304/ 316)

- Super Alloys

When to Consider Hardfacing?

- When a component needs to be replaced and repair may be a low-cost option

- When your application is in a highly corrosive atmosphere

- When wear on a component becomes an issue over it’s life cycle

Think about your equipment’s life cycle, up-time requirements, part inventory cost and cost to replace versus repair a process component…

Common Hardfacing Applications

- Steam valve components Compressor rods and sleeves

- Pump cases and components

- Mixing equipment

- Extruder screws

- Process rolls

- Centrifuge screws

- Seals

- Fan blades

- Molds

- Dies

- Plungers

- Mining equipment

- … and many more!

Every application is different. Reasons vary as to what will be the best method for hardfacing and what materials should be used. Typical materials are noted below.

Commonly applied materials for reducing wear:

(Includes wear via combinations of abrasion, impact, metal-to-metal, heat, etc.)

- Tungsten carbide

- T420 Stainless Steel

- Cobalt based materials

- Nickel based materials

Commonly applied materials for reducing corrosion:

- T316 Stainless Steel

- Hastelloy ‘C’ 276

- Cobalt based materials

- Nickel based materials

The total cost of wear and corrosion on industrial equipment each year is so high it’s incalculable. There’s a lot of opportunity to increase your process up-time by improving your wear and corrosion resistance by using hardfacing!

Mechanical properties of many substrates don’t include inherent corrosion resistance and thus require hardfacing to enhance their performance.

Ask us how we help our customers with hardfacing technology when we combine it with our machining, finishing and assembly capabilities!

So What Is Hardfacing?

Hardfacing, or hardsurfacing, is a term used when a layer of weld overlay is applied over a base material in order to prolong the life or restore dimensions of the component. The bond formed between the overlay and base metal is metallurgical.

Methods for applying hardfacing include (but are not limited to):

- Plasma Transferred Arc

- Oxy-Acetylene Torch

- TIG/ MIG/ Sub Arc

Typical base materials that are hardfaced include:

- Low & Medium Carbon Steels (ex: 1020/ 1030)

- Alloy Steels (ex: 4140, 8620)

- Stainless Steels (ex: 304/ 316)

- Super Alloys

When to Consider Hardfacing?

- When a component needs to be replaced and repair may be a low-cost option

- When your application is in a highly corrosive atmosphere

- When wear on a component becomes an issue over it’s life cycle

Think about your equipment’s life cycle, up-time requirements, part inventory cost and cost to replace versus repair a process component…

Common Hardfacing Applications

- Steam valve components Compressor rods and sleeves

- Pump cases and components

- Mixing equipment

- Extruder screws

- Process rolls

- Centrifuge screws

- Seals

- Fan blades

- Molds

- Dies

- Plungers

- Mining equipment

- … and many more!

Every application is different. Reasons vary as to what will be the best method for hardfacing and what materials should be used. Typical materials are noted below.

Commonly applied materials for reducing wear:

(Includes wear via combinations of abrasion, impact, metal-to-metal, heat, etc.)

- Tungsten carbide

- T420 Stainless Steel

- Cobalt based materials

- Nickel based materials

Commonly applied materials for reducing corrosion:

- T316 Stainless Steel

- Hastelloy ‘C’ 276

- Cobalt based materials

- Nickel based materials