August 14, 2025Thermal Spray Coating Characteristics: The Essential Guide for Industrial Performance

By Nolan Watson

When critical components operate in extreme wear, heat, or corrosive environments, thermal spray coatings provide a versatile and cost-effective way to extend service life and restore functionality.

From turbine shafts to pump sleeves to bearing surfaces, thermal spraying allows us to apply engineered surfaces tailored to specific operating demands—without distorting or metallurgically altering the base part. But to get the best results, it’s essential to understand the characteristics that define thermal spray performance. Connect with our team for a personalized consultation on how thermal spraying can extend the useful life of your equipment.

Mechanical Bond vs. Physio-Chemical Bond

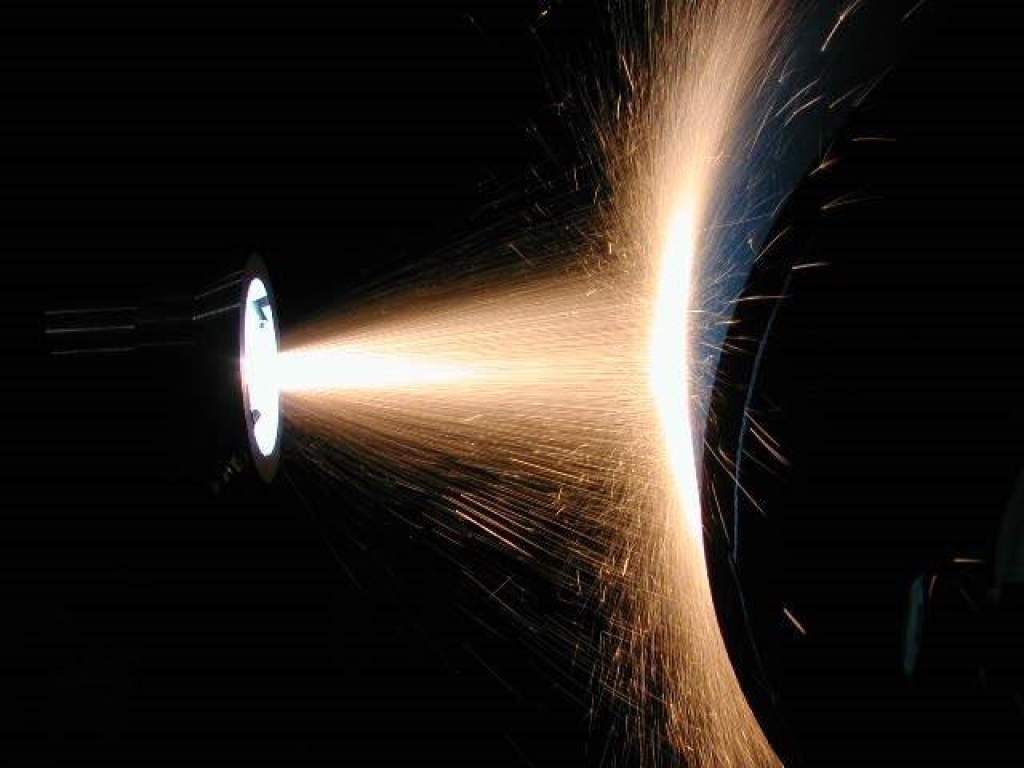

For most thermal spray processes, the bond between coating and substrate is mechanical. Molten or semi-molten particles are propelled at high velocity onto a roughened surface—usually prepared by grit blasting—where they mechanically interlock with surface protrusions.

However, in certain high-energy processes like electric arc and plasma spray, the molten particles may reach temperatures sufficient to partially fuse with the substrate. This creates what’s sometimes called a physio-chemical bond, which offers enhanced mechanical bonding.

Porosity: Advantage or Disadvantage?

All thermal sprayed coatings contain some degree of porosity. The amount depends on the process used, the coating material, and the application technique.

- When porosity is detrimental: In chemical service, permeation through the pores can attack the coating–substrate interface, leading to premature failure.

- When porosity is beneficial: In certain mechanical or thermal shock applications, higher porosity can increase flexibility and shock resistance. On bearing surfaces, controlled porosity can act as oil reservoirs, improving lubrication.

Selecting the right process/material combination allows us to tailor porosity levels to the application’s needs.

Thickness Limits and Internal Stresses

While thermal spray coatings can be built up in layers, thickness limits exist—not just for cost, but also due to the physics of the process.

- Internal stresses increase with coating thickness

- Denser coatings (lower porosity) often carry higher internal stresses

- Excessive stress can lead to lifting, cracking, or crazing of the coating as well as reduced bond strength

Proper process control and, when necessary, intermediate bond coats help mitigate these risks.

Oxides in Coatings

Oxides are a natural byproduct of thermal spraying, forming when molten particles are exposed to oxygen during flight.

- Oxide content depends on the material, process, and spraying atmosphere

- Inert gas environments or propellants can reduce oxidation

- Oxide levels influence hardness and wear resistance—sometimes beneficial, sometimes not

Hardness: Why It’s Relative

Coating hardness is not just a material property—it’s influenced by porosity, particle bonding, and oxide content. Standard hardness tests have been adapted for thermal sprayed coatings, but results are comparative, not absolute.

In practice, hardness values are most useful when comparing one sprayed coating to another, rather than to wrought or cast material data.

Adhesion and Surface Preparation

One of the most important factors in thermal spray adhesion is surface preparation. A properly prepared substrate ensures strong mechanical interlock. Factors affecting adhesion include:

- Coating material selection

- Blast profile and cleanliness

- Application technique

- Coating thickness (thicker layers increase residual stress)

Post-spray finishing must also be performed correctly—poor grinding or machining can damage the coating or compromise bond integrity.

Surface Finish Considerations

Because non-fused thermal spray coatings are inherently porous, surface finish readings can be misleading. A profilometer measures the depth of pores as well as surface texture, often producing a higher roughness value than the coating “feels” to the touch.

For functional surfaces, performance testing and application-specific inspection are better indicators of finish quality than profilometer readings alone.

Precision Finishing of Thermal Spray Coatings

When it comes to coating performance, finishing, often using the grinding process, is arguably just as important as the coating itself. Finishing is highly precise work—HFW can work to within 0.0002” on our cylindrical grinders. Grinding is used to achieve sizes on tight tolerances, dial in straightness/minimize runout, and to hit desired surface finishes.

This is complex work, and minor errors can result in costly reworks. Improper finishing technique can damage a coating, up to and including the coating becoming unbonded from the base material. Given the importance of finishing and the challenges of doing it well, it is important to note that HFW does not warrant coatings finished by others.

Why This Matters

By understanding how bond type, porosity, thickness limits, oxide content, hardness, and adhesion interact, you can make informed decisions on coating material and process selection. At HFW Industries, we combine decades of thermal spray expertise with precise process control to ensure every coating meets the operational demands of your application.

Have a part that needs protection or repair? Contact us today or visit our homepage to learn which coating or reconditioning system is right for your application.

📞 Call us at (716) 875-3380 or use our Contact Form

📧 Email: RFQ@hfwindustries.com

Want more content like this?

Sign up for our newsletter and explore these resources from our Knowledge Base:

- Overview of Thermal Spray Coatings: HVOF & Tungsten Carbide — Why these materials are key to high-performance surface protection

- What is Thermal Spraying? — A beginner-friendly overview of the process and materials used

- HVOF -- A Superior Alternative to Chrome — Why HVOF coatings often outperform chrome in durability, cost, and turnaround time

- Precision Grinding at HFW — A look inside our plant, detailing HFW's precision finishing capabilities and CNC grinding

- How HFW Extends Equipment Life — Real-world example of innovation in action within the chemical industry

- How Does HFW Serve the Turbomachinery Industry? — Learn about HFW's one-source repair and manufacturing strategy for turbines, rotors, and other turbomachinery equipment

- What is Electrical Mechanical Runout (EMRO)? — Learn how EMRO shaft inspection can help ensure operations run smoothly

- What are HFW's Hardfacing Capabilities? — Explore how HFW’s hardfacing expertise restores industrial equipment with proven weld procedures and precision inspection