In power generation, oil & gas, chemical processing and plastics, and high-tech manufacturing, most reliability problems don’t come from exotic failures. They come from familiar components that simply don’t last as long as they should.

Valve internals, wear surfaces, rotating components, and sealing areas operate in environments defined by heat, corrosion, erosion, and mechanical stress. When protective overlays or rebuilds fail prematurely, the real cost isn’t the repair; it’s lost confidence in the equipment and the planning assumptions built around it.

One of the most common and costly failure modes we see across industries is hardfacing delamination.

Delamination Might Be a Reliability Problem, Not a Material Problem

When delamination occurs, it’s tempting to focus on the material itself. In reality, delamination is often a process control problem.

Across many industries, hardfacing might fail not because the alloy was wrong but because:

- Preheat and interpass temperatures were not tightly controlled

- Dilution was unmanaged

- Transition layers were omitted

- Post-weld cooling or heat treatment was inconsistent

Each of these factors may seem small in isolation. Together, they determine whether a component delivers years of service or fails far too early.

A Case That Reinforced This Lesson

A large southeastern utility contacted HFW after experiencing Stellite® delamination on valve components.

The components included valve discs and seats manufactured from chromium-molybdenum steel, with valve stems produced from an iron-base superalloy. The application itself was not unusual. What mattered was reliability.

The objective was simple: eliminate delamination and restore confidence in service life expectations.

Why Process Integration Matters

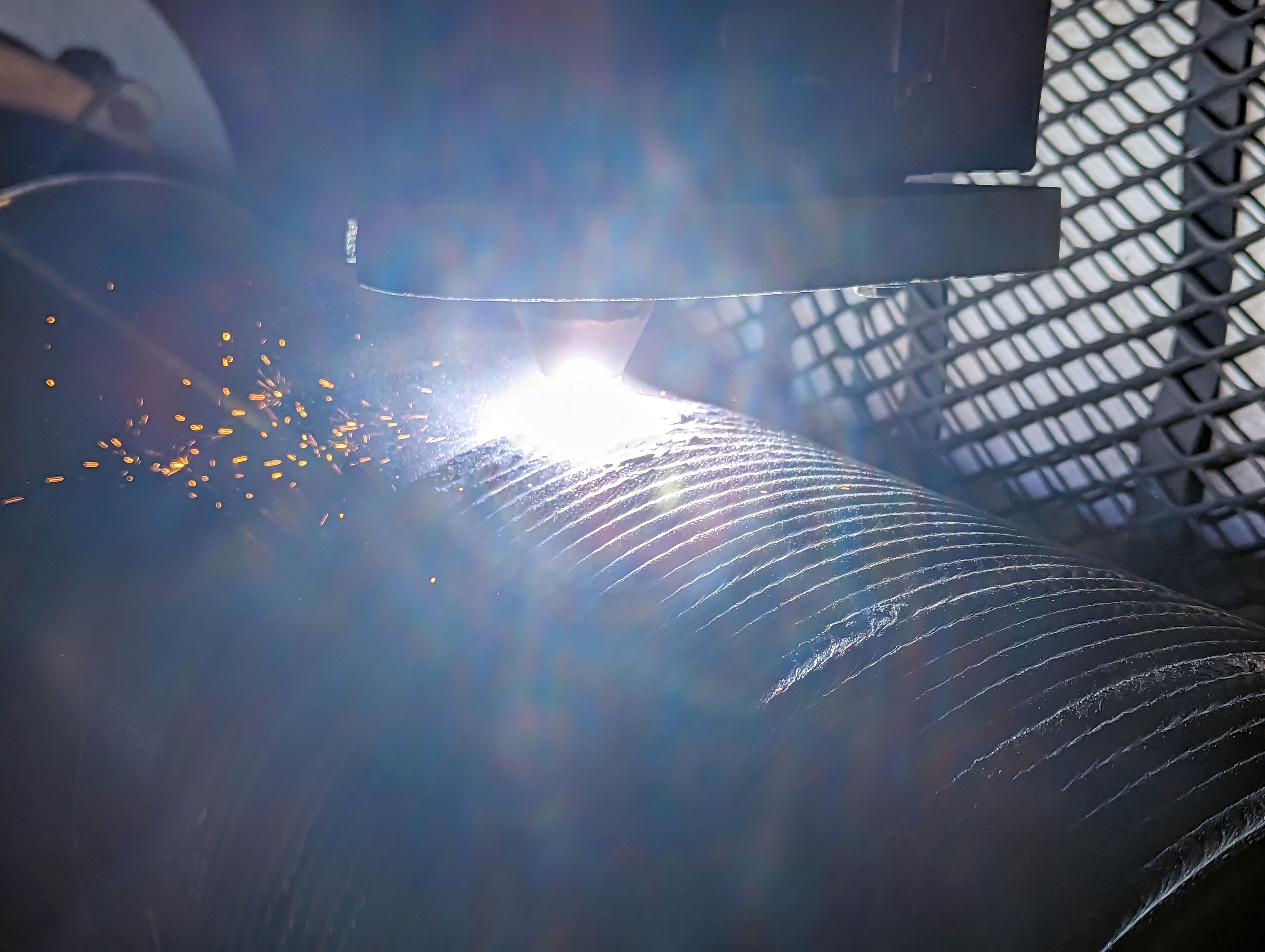

For this project, the focus was not on “reapplying a coating” but on engineering the entire workflow around reliability.

That meant:

- Applying proper preheat and strict interpass temperature control

- Using butter layers to manage dilution and improve fusion

- Controlling post-weld cooling treatment

- Inspecting hardfaced surfaces using liquid penetrant and ultrasonic testing by an AWS-certified inspector

Just as important, all of this occurred within a single facility, under one quality system.

The Result: Reliability Measured in Years, Not Months

When we checked in with the customer, the valve components had been in service for five years, operating under demanding conditions with the hardfacing intact.

From a reliability standpoint, that outcome is the real measure of success. It lengthened equipment life, stabilized maintenance planning, and removed a source of operational risk.

What Reliability Teams Can Take From This

This case reinforces a broader point that applies well beyond valves or any single alloy:

Long equipment life is engineered through process discipline, not assumed through material selection.

Whether work is done in-house or outsourced, reliability improves when:

- Welding, machining, grinding, thermal spraying, and inspection are coordinated

- Heat input and sequencing are controlled

- Documentation is consistent and traceable

- Accountability for final performance is clear

A one-source approach is not about convenience. It is about reducing the variables that shorten equipment life.

A Question for Reliability and Maintenance Engineers

If you’ve dealt with premature wear, delamination, or rebuilds that didn’t last as expected:

- Was the failure mode obvious up front?

- Or did it trace back to process details that were hard to see after the fact?

Sharing those lessons helps all of us build more reliable systems. If this perspective is useful, feel free to share it with your team or connect with us on LinkedIn.

And if you are experiencing recurring outages or emergency repair situations, let’s discuss a plan to keep your equipment running.

📧 RFQ@hfwindustries.com or 📞 (716) 875-3380

Want More Content Like This?

Sign up for our newsletter and explore these resources from our Knowledge Base: