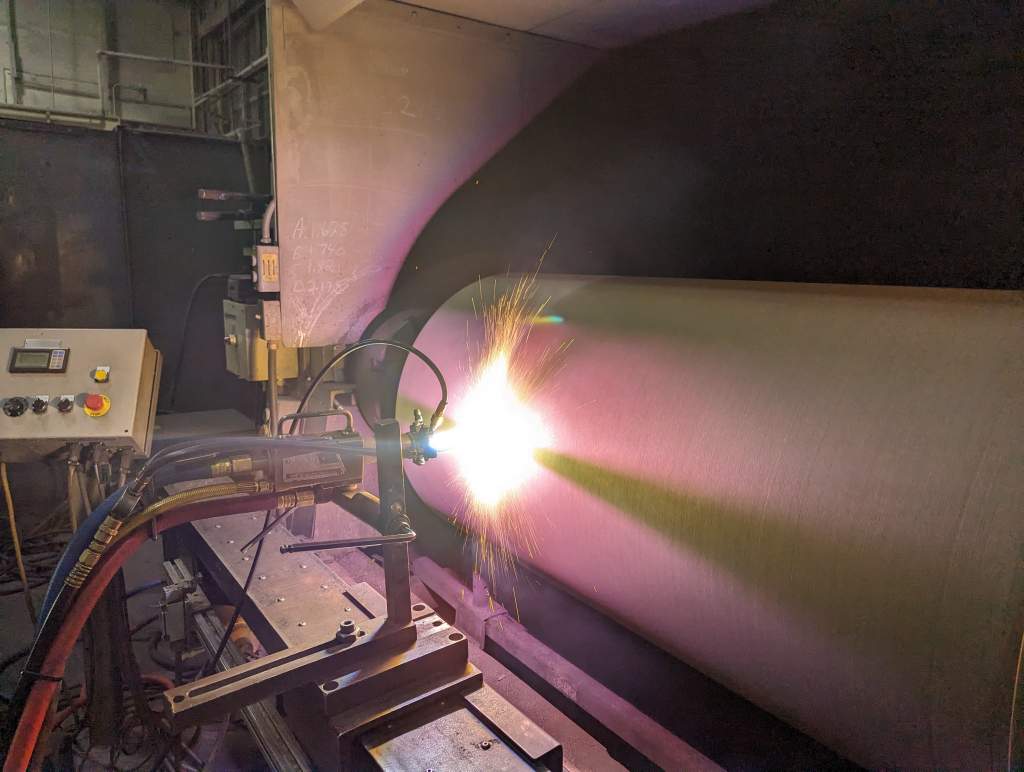

September 17, 2021HVOF Thermal Spraying with Tungsten Carbide

HFW Industries has been providing thermal spray coating solutions since 1947 and High Velocity Oxy-Fuel (HVOF) coatings for over 20 years.

In addition to the HVOF process, HFW also applies thermal spray coatings using flame spray, electric arc metallizing and plasma spray processes.

During the 1980’s the HVOF process was developed to be an accessible market alternative to Union Carbide’s D (detonation) gun process.

HVOF uses the internal combustion of fuel gases (ex: propylene, propane, hydrogen or kerosene with oxygen) to produce a hypersonic gas stream into which the coating material is fed. The powder is heated and propelled by the gas stream at hypersonic velocities against the workpiece where molten coating particles impact and form a homogenous coating structure.

Tungsten Carbide/ Cobalt/ Chrome coatings can be used for abrasion and sliding wear resistance when some corrosion protection is required. Typical applications include piston/ compressor rods, sleeves, fan blades, mechanical seal faces, process rolls, and at times as a replacement for chrome plating.

HFW Industries offers ISO 9001:2008 registered services for manufacturing and repairing equipment used in demanding applications that can utilize our expertise in combining our coating technology with our precision machining, finishing and assembly capability.

We focus on One Source solutions that reduce costs, shorten lead times and eliminate hassles of working with multiple vendors.

Coating Properties

- Microhardness: 1,000-1,350 DPH (300g)

- Bond Strength (per ASTM C633): 10,500+ PSI

- Porosity: < 1%

- Est. Max. Service Temp.: 1,000 ºF

- Est. Surface Roughness as Sprayed: 150-250 Ra

- Possible Surface Roughness as Finished: 1-5 Ra

HFW Industries has been providing thermal spray coating solutions since 1947 and High Velocity Oxy-Fuel (HVOF) coatings for over 20 years.

In addition to the HVOF process, HFW also applies thermal spray coatings using flame spray, electric arc metallizing and plasma spray processes.

During the 1980’s the HVOF process was developed to be an accessible market alternative to Union Carbide’s D (detonation) gun process.

HVOF uses the internal combustion of fuel gases (ex: propylene, propane, hydrogen or kerosene with oxygen) to produce a hypersonic gas stream into which the coating material is fed. The powder is heated and propelled by the gas stream at hypersonic velocities against the workpiece where molten coating particles impact and form a homogenous coating structure.

Tungsten Carbide/ Cobalt/ Chrome coatings can be used for abrasion and sliding wear resistance when some corrosion protection is required. Typical applications include piston/ compressor rods, sleeves, fan blades, mechanical seal faces, process rolls, and at times as a replacement for chrome plating.

HFW Industries offers ISO 9001:2008 registered services for manufacturing and repairing equipment used in demanding applications that can utilize our expertise in combining our coating technology with our precision machining, finishing and assembly capability.

We focus on One Source solutions that reduce costs, shorten lead times and eliminate hassles of working with multiple vendors.

Coating Properties

- Microhardness: 1,000-1,350 DPH (300g)

- Bond Strength (per ASTM C633): 10,500+ PSI

- Porosity: < 1%

- Est. Max. Service Temp.: 1,000 ºF

- Est. Surface Roughness as Sprayed: 150-250 Ra

- Possible Surface Roughness as Finished: 1-5 Ra