February 4, 2026How Chemical Mixers & Agitators Are Repaired After Corrosion & High Wear

By Nolan Watson, Technical Writer at HFW Industries

Mixers and agitators in chemical processing plants operate in some of the most demanding conditions in manufacturing. Corrosive chemistries, abrasive media, heat, and continuous operation all contribute to wear patterns that are difficult to predict and expensive to ignore.

When these components degrade, the challenge isn’t simply restoring dimensions. It’s rebuilding them in a way that improves reliability, maintains tight tolerances, and performs in a specific chemical environment.

That’s where a turnkey, after-market approach matters.

One-Source Reliability for the Chemical Processing Industry

For over 70 years, HFW Industries has supported chemical processors with integrated manufacturing and repair solutions for critical rotating equipment. Our one-source reliability model combines:

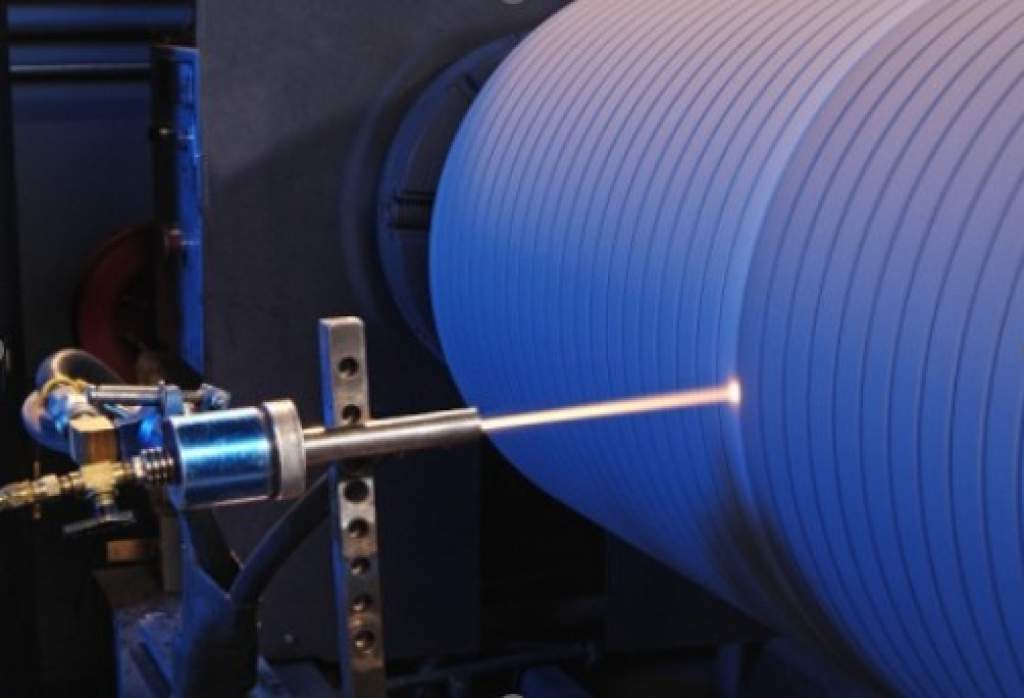

- Thermal spray coatings

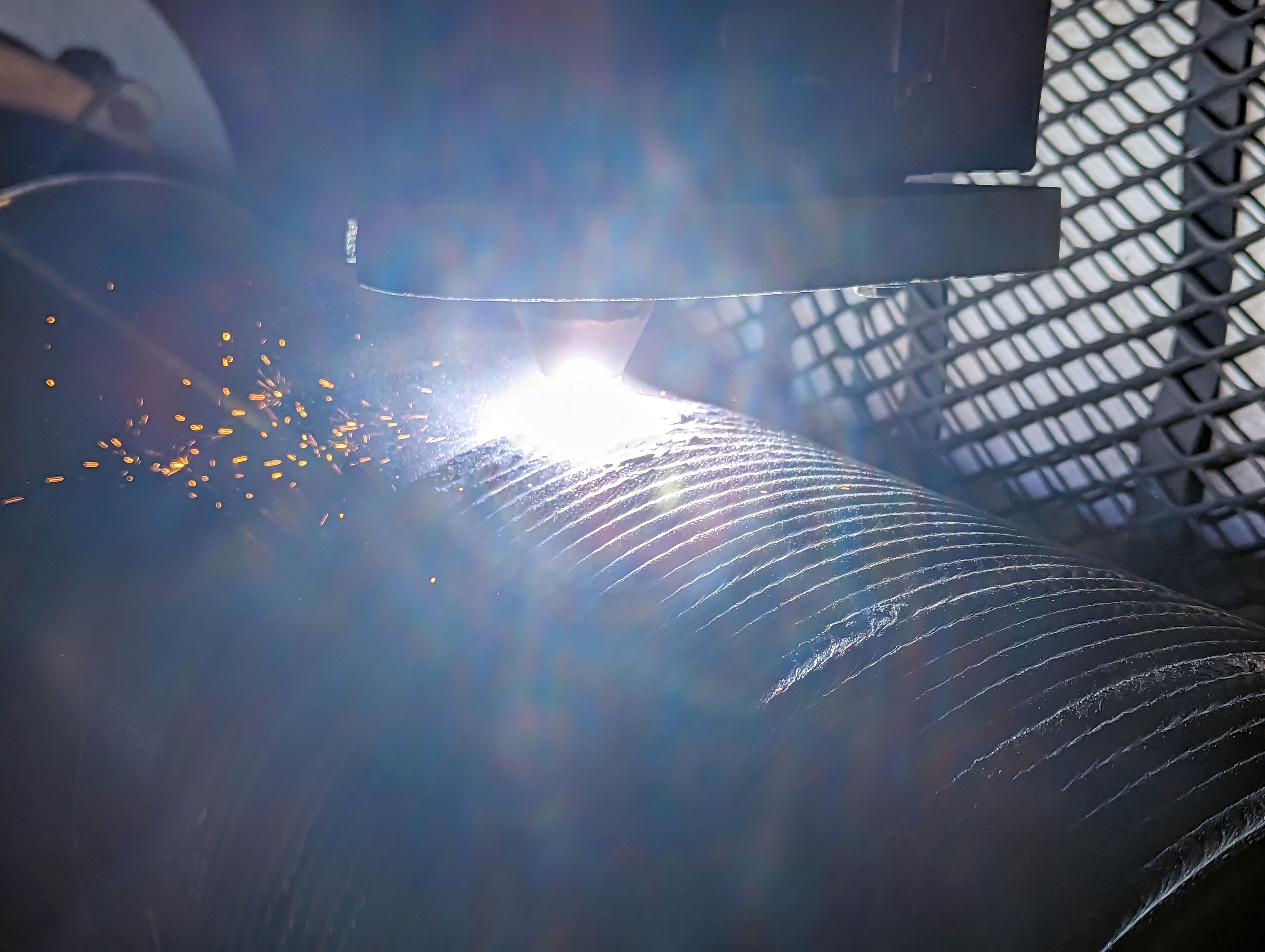

- Hardfacing weld overlays

- Precision CNC machining

- Grinding and finishing

- Inspection and final assembly

This allows us to move quickly, control quality at every step, and engineer repairs around how the equipment actually operates, not just how it measures on a drawing.

How Mixers and Agitators Fail

In chemical service, the most common failure modes we see are corrosion and wear, often acting together. The base material may be sound, but prolonged exposure to aggressive chemistry gradually degrades working surfaces, shaft journals, and interfaces.

Common base materials we encounter include:

- Stainless steels (most common for mixer shafts)

- Super duplex stainless steels

- Hastelloy® and Inconel® (application-dependent)

Material selection alone rarely solves the problem. Performance depends on how the surface interacts with the process chemistry, which is why surface engineering plays such a critical role in long-term reliability.

Choosing the Right Repair Strategy: Not One-Size-Fits-All

Every repair starts with understanding the application. Chemical environments vary widely, and customers are understandably guarded about process details. As a result, there is no universal solution—only informed engineering choices.

Machining Alone

Used when wear is minimal and the base material remains suitable for service.

Thermal Spray

Ideal when minimal heat input is required and no major dimensional restoration is needed.

- Mechanically bonded coating

- Typical finished thickness: ~0.010–0.050 in

- Used where corrosion and moderate wear are primary concerns

Hardfacing Weld Overlays

Selected for severe operating environments where impact, heavy wear, or aggressive corrosion demand a metallurgical bond.

- Higher heat input

- Suitable for heavier-duty components

- Allows significant profile restoration (e.g., mixer screws and paddles)

Chemical compatibility is always evaluated before selecting a coating or overlay. What performs well in one process may fail prematurely in another.

Proprietary Materials: Where HFW 512 Fits

HFW 512 is a proprietary nickel-based alloy thermal spray material developed for environments involving corrosion with some wear. In certain chemical applications, it has delivered significant service life improvements compared to ceramic coatings or some nickel-based alloys.

That said, HFW 512 is not a blanket solution. Its success depends on the specific chemistry, operating conditions, and failure mechanisms involved. When appropriate, it has proven to be a powerful tool. When it’s not the best suited solution, we recommend alternatives based on experience and data.

Precision Matters: Tolerances & Quality

Chemical mixers and agitators demand precision to operate reliably. HFW regularly works to tight dimensional and runout requirements, including:

- Typical shaft tolerances: 0.0005”

- Tighter tolerances down to 0.0002” TIR when geometry allows

Quality control measures are selected based on the repair scope and risk profile and may include:

- Liquid penetrant inspection of weld overlays

- Runout, straightness, and concentricity verification

The goal is not just compliance; it’s repeatable, predictable performance in service.

Short Lead Times for Chemical Processors Without Cutting Corners

Because coating, welding, machining, grinding, and inspection are all in-house specialties, HFW is able to support short lead times, including emergency repairs, without sacrificing quality.

This integrated execution reduces handoffs, eliminates vendor delays, and keeps accountability clear, especially important when downtime is costly.

Experience That Shows in the Results

HFW’s long-standing relationships in the chemical processing industry are built on results: longer service life, fewer unplanned outages, and repairs engineered for real operating conditions.

Whether restoring mixer shafts, rebuilding agitator assemblies, or applying advanced surface solutions, our focus remains the same: reliability you can plan around.

Turnkey After-Market Support for Chemical Processing Equipment

If you’re facing corrosion-driven failures, recurring wear, or short repair cycles in mixers or agitators, HFW Industries offers a technically grounded, application-specific approach backed by decades of experience.

Contact HFW Industries to discuss your equipment, your environment, and your options.

Contact HFW Industries for Emergency Chemical Equipment Repairs

Need to discuss a component rebuild, coating application, or emergency repair? Let's talk. Connect with our engineering team today to get a customized solution for your emergency needs.

📞 Call us at (716) 875-3380

📧 Email: RFQ@hfwindustries.com

Additional Technical Resources for Chemical Processing Professionals

Sign up for our newsletter and explore these resources from our Knowledge Base:

- How HFW Extends Equipment Life for the Chemical Processing Industry — Real-world example of innovation in action: 30x increase in service life for a chemical client

- Reducing Assembly Time by 75% at 1/3 the Cost — Learn how HFW's one-source strategy can streamline our customer's processes and rein in costs

- Overview of Thermal Spray Coatings: HVOF & Tungsten Carbide — Why these materials are key to high-performance surface protection

- How to Prevent Hardface Delamination — Learn how HFW increased the reliability of equipment for a southeastern utility by redesigning the entire workflow around reliability

- Precision Grinding at HFW — A look inside our plant, detailing HFW's precision finishing capabilities and CNC grinding

- What are HFW's Hardfacing Capabilities? — Explore how HFW’s hardfacing expertise restores industrial equipment with proven weld procedures and precision inspection

FAQ: Chemical Mixer & Agitator Repair in Chemical Processing Plants

What causes mixers and agitators to fail in chemical processing plants?

The most common failure modes we observe for chemical mixers and agitators are corrosion and wear—potentially both at the same time. Even when the base material remains structurally sound, aggressive chemistries, abrasive media, heat, and continuous operation gradually degrade shafts, journals, screws, and interfaces.

Can chemical mixers and agitators be repaired instead of replaced?

Yes. In many cases, repair or remanufacture is more cost-effective than replacement, especially when the base material is still viable. Rebuilding worn areas, restoring geometry, and applying the right surface engineering solution can significantly extend service life and reduce total cost of ownership.

What materials are commonly used for mixer and agitator shafts in chemical processing?

Most mixer and agitator shafts in chemical service are made from stainless steel, though super duplex stainless steels, Hastelloy®, and Inconel® are also used depending on the chemical environment. Material selection alone rarely solves reliability issues—surface condition and chemistry compatibility are critical.

How do you decide between machining, thermal spray, or hardfacing?

The repair strategy depends entirely on the application:

- Machining alone is used when wear is minimal and corrosion is limited.

- Thermal spray coatings are ideal when minimal heat input is required and corrosion with moderate wear is the primary concern.

- Hardfacing weld overlays are selected for severe environments involving impact, heavy wear, or aggressive corrosion where a metallurgical bond is required.

There is no one-size-fits-all solution.

What is the difference between HVOF thermal spray and hardfacing?

Thermal spray coatings are mechanically bonded, involve minimal heat input, and typically finish at ~0.010–0.012 inches thick. Hardfacing weld overlays involve higher heat input, create a metallurgical bond, and allow heavier buildup and profile restoration for demanding chemical processing applications.

What is HFW 512, and when is it used?

HFW 512 is a proprietary nickel-based alloy thermal spray material developed for environments involving corrosion with some wear. In select chemical processing applications, it has delivered dramatic service life improvements—including one documented case with a 30× increase in component lifespan. However, HFW 512 is not a blanket solution and is applied only when the chemistry and operating conditions support it.

How tight are tolerances for chemical mixer and agitator repairs?

HFW regularly machines and finishes components to 0.0005” tolerances on mixer and agitator shafts. Tighter requirements down to 0.0002” TIR are achievable when geometry allows.

How is quality verified during chemical equipment rebuilds?

Inspection methods are selected based on risk and application and may include liquid penetrant inspection of weld overlays, verification of runout, straightness, and concentricity, and balance considerations. The goal is consistent, repeatable performance in service, not just dimensional compliance.

Why does a turnkey, one-source approach matter for chemical equipment repair?

A turnkey, one-source approach reduces vendor handoffs, shortens lead times, improves quality control, and keeps accountability clear. By performing coating, welding, machining, grinding, inspection, and assembly in-house, repairs are engineered around how the equipment actually operates, not just individual process steps.

Can HFW support short lead times or emergency chemical equipment repairs?

Yes. Because all core processes are performed in-house, HFW supports short lead times and emergency repairs without cutting corners. This is especially important in chemical processing environments where downtime is costly and unpredictable.

How do these repairs improve reliability and reduce downtime?

By addressing corrosion and wear at the surface level, restoring proper geometry, and holding tight tolerances, rebuilt mixers and agitators operate more predictably, last longer between maintenance cycles, and reduce the risk of unplanned outages, improving overall plant reliability.

Is every chemical mixer and agitator repair application-specific?

Yes. Chemical processing environments vary widely, and performance depends on the interaction between materials, coatings, operating conditions, and chemistry. HFW evaluates each application individually and recommends solutions based on experience, data, and engineering judgment.

Attribution Statements

- Hastelloy® is a registered trademark of HAYNES INTERNATIONAL, INC.

- Inconel® is a registered trademark of HUNTINGTON ALLOYS CORPORATION.