June 23, 2025HFW 512: The Key to Long Equipment Lifespans

By Jack Watson

Thermal Spray Reduces Costs in the Chemical Industry: 30x Increase in Service Life

At HFW, we don’t just talk about saving our customers time and money—we back it up with proven data. Contact our team to discuss how we can deliver transformative results for your operation.

From Months to Years: A Proven Success Story

In the 1980s, a customer in the chemical processing industry approached HFW with a major challenge: its rolls were only lasting two months in service. Short lifespans like these can lead to high maintenance costs and expensive downtime within the chemical industry—problems that impact production efficiency and profitability.

HFW quickly improved roll performance to 4–5 months using our standard thermal spray coating processes. But we didn’t stop there.

The Power of the HFW 512 Alloy

The real breakthrough came when we began experimenting with HFW 512, our proprietary nickel-based alloy thermal spray powder that’s been successfully applied across multiple industries. Working in partnership with the customer’s metallurgist, we applied HFW 512 using our HVOF thermal spray process.

The results were significant:

- Roll lifespan increased from months to 5–6 years in service

- Long-term cost savings far exceeded the initial coating investment

- With over 40 years of documented performance data, this is not just a claim—it’s a proven step-change improvement

Why This Matters for Chemical Processors

In chemical manufacturing, downtime is more than an inconvenience. It’s an expense that can cost thousands of dollars per hour. By extending roll life with advanced thermal spray coatings, HFW helps customers:

- Reduce roll downtime and maintenance-related shutdowns

- Improve reliability and production efficiency

- Lower total cost of ownership for critical equipment

- For plant managers and purchasing teams, this is actionable data that justifies investment and drives measurable ROI

Real Results Backed by Decades of Data

It’s one thing to say you can improve equipment performance. It’s another to have decades of proof.

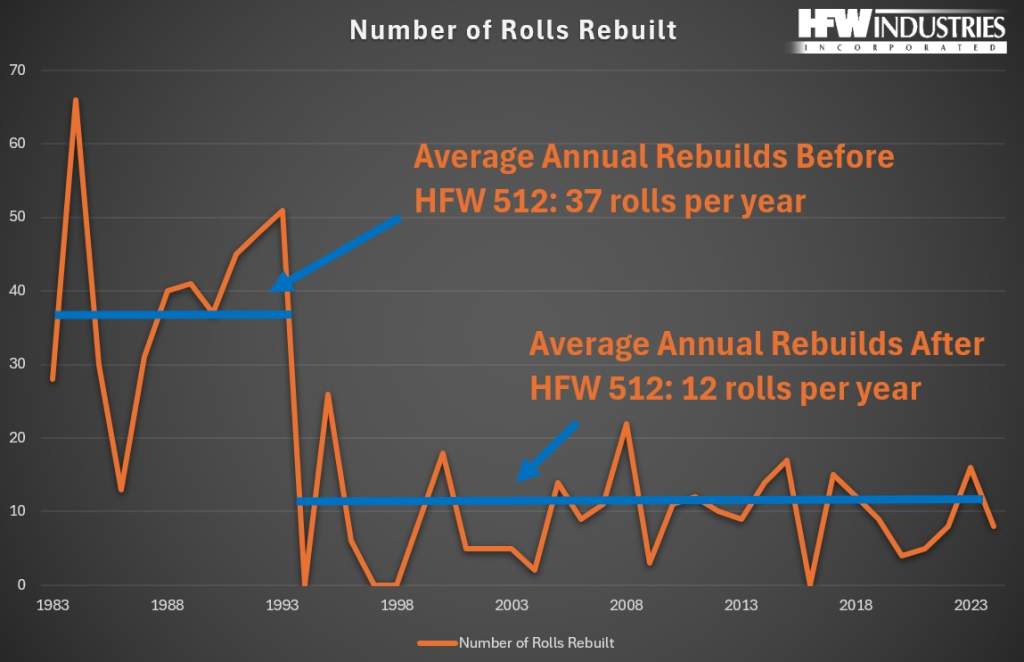

The attached graph shows the dramatic reduction in the number of rolls HFW rebuilt for our customer after adopting HFW 512. This is the power of combining metallurgical expertise with advanced thermal spray coating technology.

Work With HFW

If you are a chemical processing facility or another type of manufacturer that is struggling with frequent roll failures, high maintenance costs, or costly downtime, HFW can help. Our team has the experience, technology, and proprietary materials like HFW 512 to deliver proven, long-term results.

Have a part that needs protection or repair? Contact us today or visit our homepage to learn which coating or reconditioning system is right for your application.

📞 Call us at (716) 875-3380 or use our Contact Form

📧 Email: RFQ@hfwindustries.com

Want to explore more? Start with these expert resources from our Knowledge Base:

- What is Thermal Spraying? — A beginner-friendly overview of the process and materials used

- Overview of Thermal Spray Coatings: HVOF & Tungsten Carbide — Why these materials are key to high-performance surface protection

- HVOF -- A Superior Alternative to Chrome — Why HVOF coatings often outperform chrome in durability, cost, and turnaround time

- Precision Grinding at HFW — A look inside our plant, detailing HFW's precision finishing capabilities and CNC grinding

- How Does HFW Serve the Turbomachinery Industry? — Learn about HFW's one-source repair and manufacturing strategy for turbines, rotors, and other turbomachinery equipment

- What is Electrical Mechanical Runout (EMRO)? — Learn how EMRO shaft inspection can help ensure operations run smoothly

- What are HFW's Hardfacing Capabilities? — Explore how HFW’s hardfacing expertise restores industrial equipment with proven weld procedures and precision inspection