November 22, 2023Chemical Processing Capabilities

By Jack Watson

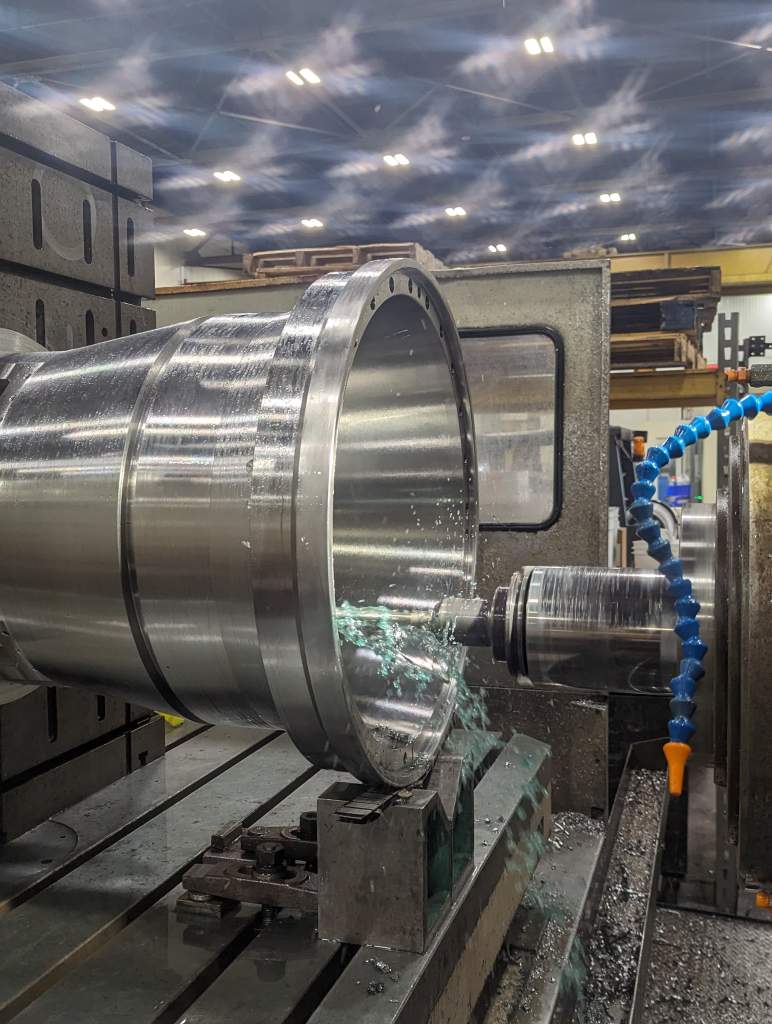

HFW Industries offers One Source capabilities as a manufacturer of original equipment and rebuilder of machine components using wear and corrosion resistant coatings (thermal spraying using HVOF, plasma spray, metallize, Rokide™, and spray weld, or hardfacing weld overlays via PTA, ARC, TIG, or MIG). We complement these services with precision machining, precision finishing, and assembly for the chemical processing industry.

- One Source service with chemical processing equipment experience since 1947

- Manufacturing services (machining, finishing, assembly, etc.)

- Rebuild machinery and extend component service life by incorporating thermal spray coatings & hardfacing technology.

With over 75 years of experience, HFW Industries has become recognized as the Chemical Industry leader in the integration of high-performance surface enhancements with state of the art manufacturing technology. In many areas of the industry, we combine Thermal Spray Coatings and Weld Overlays with our CNC Machining, Precision Grinding, and Assembly capabilities that provide cost effective solutions to common operating problems such as abrasion, wear, loss of profile, erosion, and corrosion.

Typical applications include, but are not limited to:

Capital Equipment

- Valve Guides

- Valve Bodies & Stems

- Gate Valves

- Diverter Valves

Rolls- Manufacture and Repair

- Feed Rolls

- Idler Rolls

- Godet Rolls

- Calendar

- Nip Rolls

- Steam Rolls

- Dryer Rolls

Gear Boxes- Repair

Feed Screws and Segments

Mixer Components- Manufacture & Repair

- Paddles (Hastelloy/ Stellite/ Stainless Steel)

- Shafts

- Shaft Sleeves

Shafts- Manufacture & Repair

- Reactor Shafts

- Pump Shafts

- Agitator Shafts and Assemblies

Bearing and Seal Housings

Pump Housing/ Component- Repair

Centrifuge Components Manufacture & Repair

- Screws

- Barrels/ Bowls

- Bowl Ends/ Flanges